Nanocomposite Technology

An advanced, proprietary technology that allows operators to detect leaks early with little exposure to liquid hydrocarbons.

An advanced, proprietary technology that allows operators to detect leaks early with little exposure to liquid hydrocarbons.

Direct-C’s polymer nanocomposite-based sensors offer a novel approach to oil and gas asset monitoring, particularly for chemical leak detection. The sensors are formulated by mixing nanoparticles, including carbon nanotubes, into proprietary polymers that are capable of absorbing chemicals that they need to detect. The polymer also provides the advantage of being hydrophobic, meaning it is unaffected by water and therefore suitable for areas below the groundwater table.

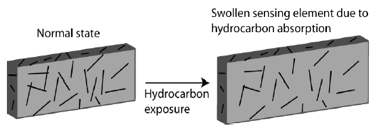

With the presence of hydrocarbon molecules, the polymer nanocomposite swells to instantly detect liquid hydrocarbon leaks. The novel nanocomposite formulated for leak detection application is not affected by natural gas, thus eliminating false positives from background gas. Instead, the polymers are tuned to detect liquid C5 to C24 hydrocarbons.

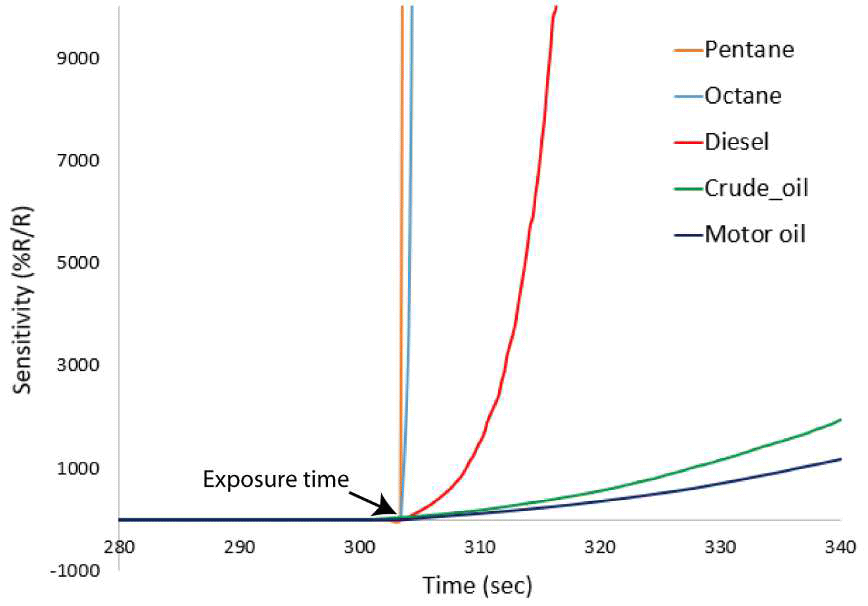

The nanocomposite sensors are extremely sensitive in all cases. Figure A shows the nanocomposite sensitivity to various liquid hydrocarbons by comparing the exposure times with the reaction time, in seconds.

The type of leaking hydrocarbon is determined because detection methods are based on the rate of change in the sensor’s resistance. The technology meets a big need in the marketplace because it enables detection in areas where several different hydrocarbon products are being stored or transported. Customers are able to remotely see which specific hydrocarbon product is leaking before dispatching their response teams.

The nanocomposite polymers are designed specifically to detect liquid hydrocarbon molecules, therefore they make indispensable additions for all liquid hydrocarbon-producing assets. The most common use cases for the nanocomposite polymers include monitoring systems deployed for above-ground pipelines, pipelines over water crossings, below-ground pipelines, wellheads and flanges.

Multifunctional sensors allow you to not only pick and choose what you want to monitor, but also to gather critical field data on environmental conditions that could otherwise result in product loss or inoperable conditions.

Discover multifunctional capabilities

Direct-C’s monitoring systems disrupt traditional monitoring methods by digitizing leak detection and monitoring other critical field data to create ease-of-use for the operator and extend the life of oil and gas infrastructure.

See our IIoT Systems

Direct-C’s monitoring systems now offer produced water leak detection and low-temperature alerts.

Learn more about how multifunctional sensors can provide critical field data to automate your asset monitoring process.

SENSORS